What we do

Solutions & Expertise

Optical Manufacturing is our Expertise

We provide an extensive

range of optical lense services.

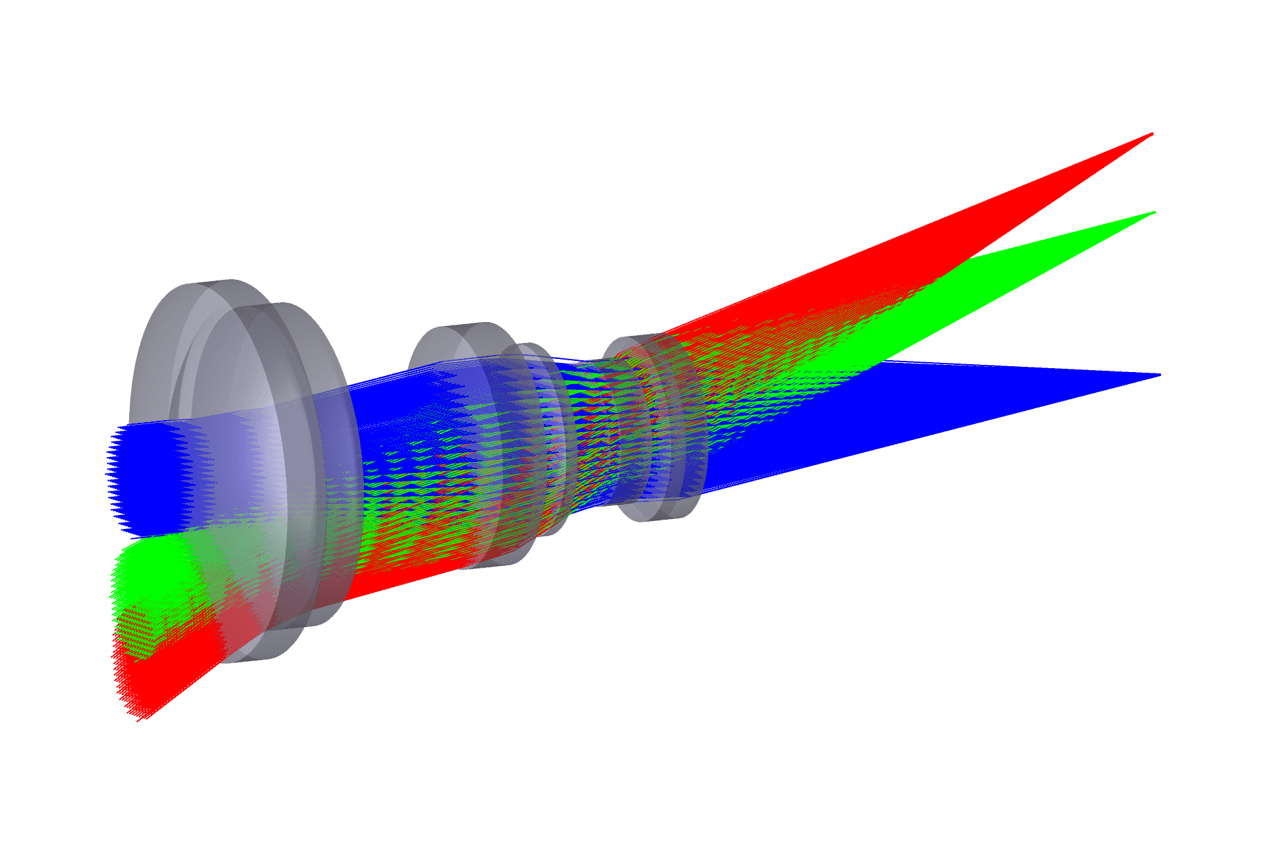

Custom Optical Design

LightPath offers custom lens design tailored to your specifications. Our in-house engineering and manufacturing teams collaborate closely with you to create lenses that perfectly meet your unique needs.

Fabrication

LightPath offers both standard and custom-made lenses. These are expertly designed by our optical engineers or manufactured according to your specifications.

Materials

With well over 200 moldable glass types available, LightPath focuses on a select few to ensure our customers receive the fastest lead times at the lowest cost.

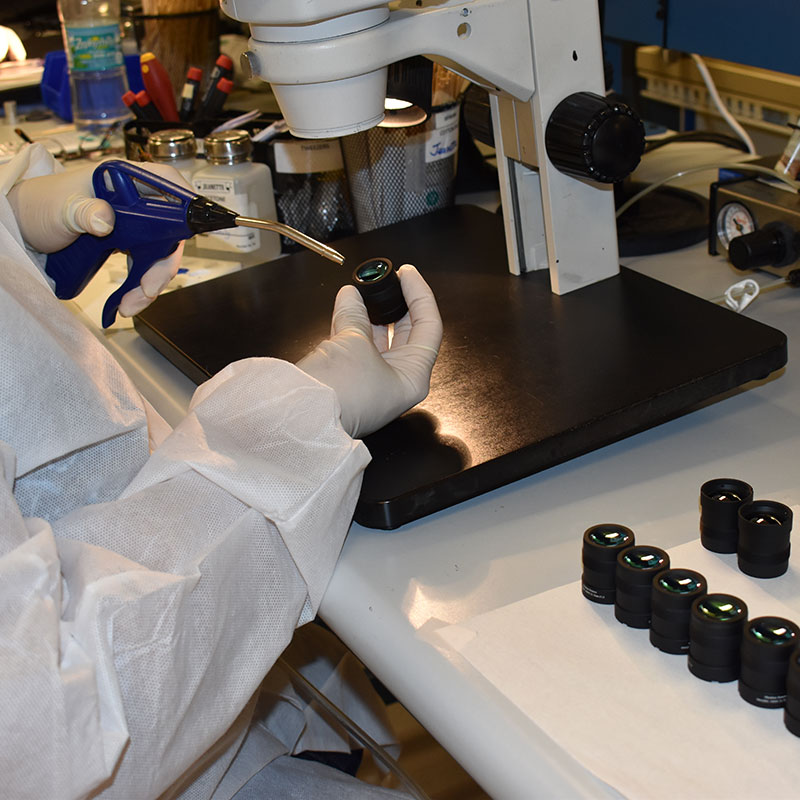

Assembly & Integration

By leveraging our broad optical component portfolio, LightPath has been implementing sophisticated integrated optical assemblies.

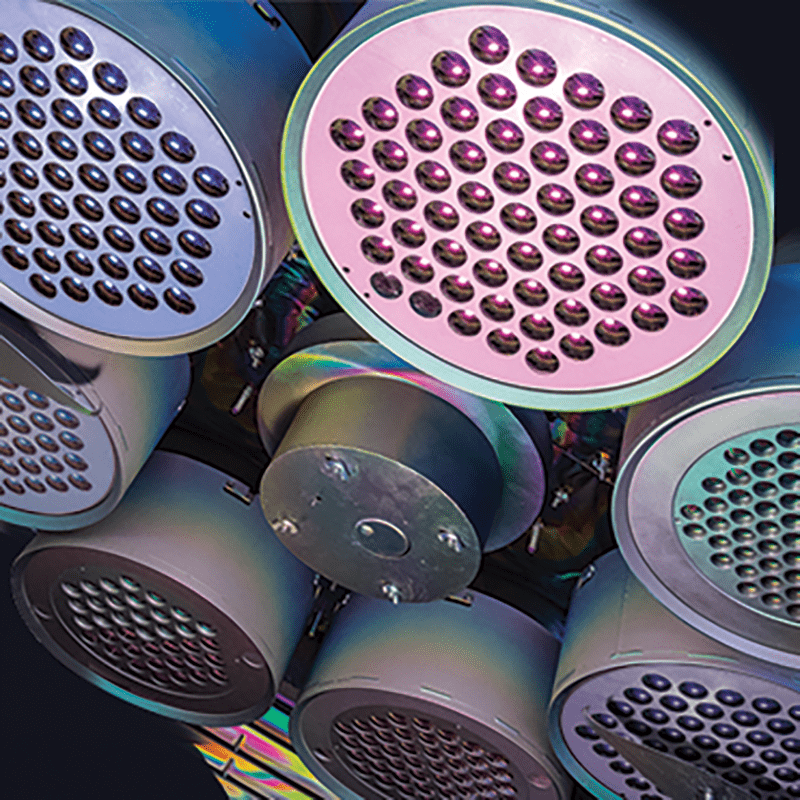

Optical Coating

LightPath offers a variety of optical coatings to support your optical needs and achieve the best performance from your systems.

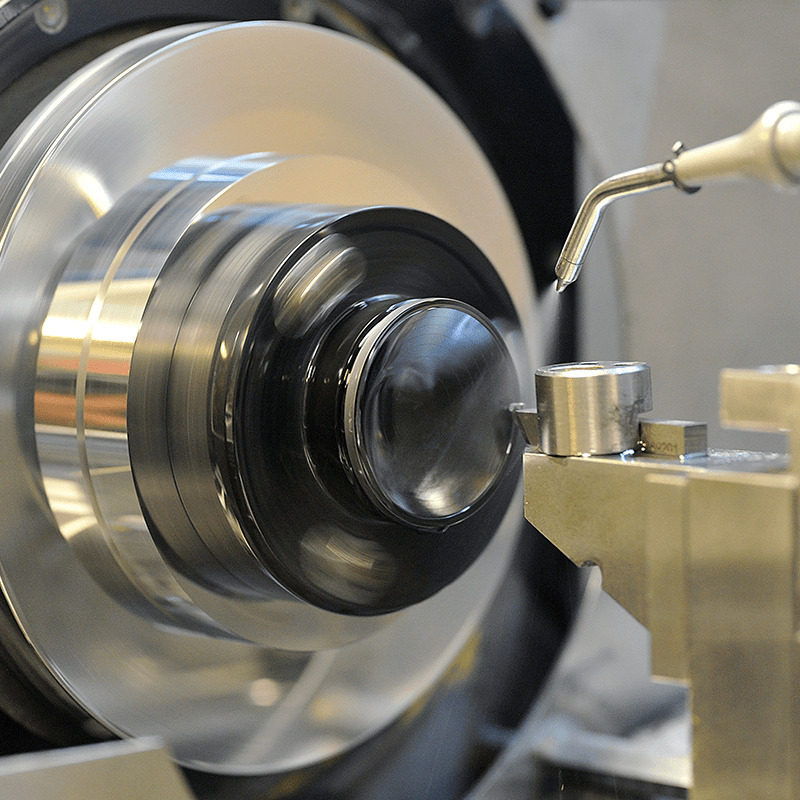

Diamond Turning

With over 20 in-house single point diamond turning machines, we produce rotationally symmetric spheres, aspheres, and diffractive lenses, including those with diameters as small as 3mm.

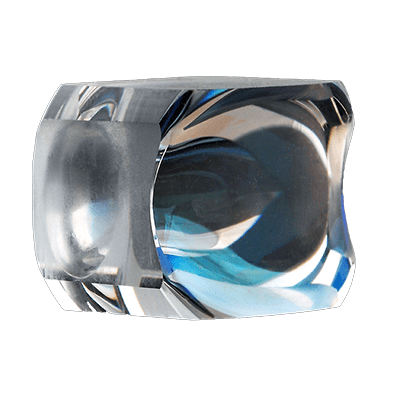

Freeform Optics

Freeform optics, which lack symmetry constraints, provide superior optical performance compared to traditional designs, making them essential for applications like AR/VR, automotive LIDAR, military optical systems, and medical technologies. At LightPath Technologies, we leverage decades of precision lens molding experience to produce high-volume, precision-molded freeform optics, ensuring advanced solutions for cutting-edge applications.

Infrared Glass Manufacturing

LightPath Technologies, with extensive experience in Chalcogenide Glass production, manufactures a variety of these glasses at its Orlando, Florida facility. Utilizing our proprietary molding technology, we produce Black Diamond™ Chalcogenide glasses in 120mm diameter boules and can expand them to larger diameters. Our BD6 and BD2 glasses, produced up to 10 metric tons annually, maintain consistent refractive indices whether molded or polished. Additionally, in November 2021, LightPath received an exclusive license from the US Naval Research Laboratories for new Chalcogenide glasses, now being transitioned into production.

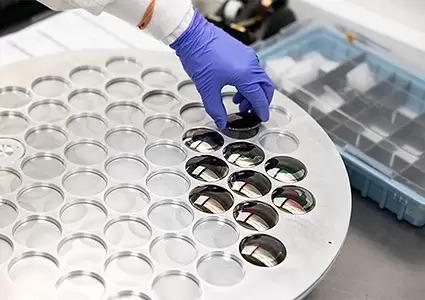

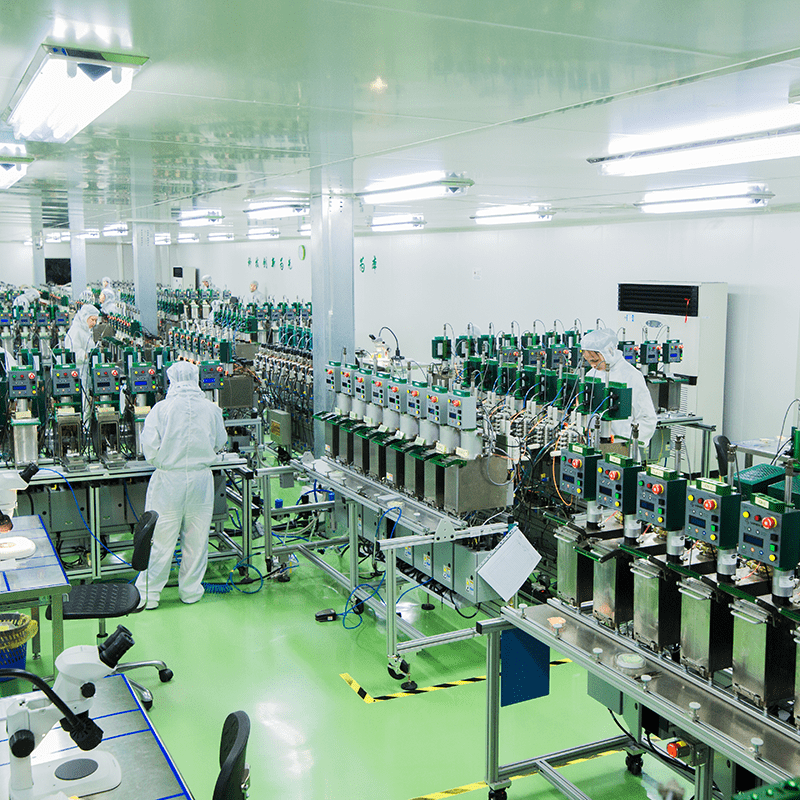

Precision Molding Glass

Molding is the most consistent and economical way to produce high-volume aspheres, and LightPath has perfected this method to offer the most precise aspheric lenses available

Quality & Testing

At LightPath, Quality Control is crucial in optical components and systems manufacturing. Utilizing state-of-the-art metrology equipment, both operators and quality inspectors measure, control, and optimize processes throughout production runs. This ensures precise process control and high-quality outcomes.