A GLOBAL LEADER

Precision Molded Optics

LightPath Technologies is a global leader in precision molded optics, specializing in the high-volume production of high-performance aspheric lenses. Leveraging decades of experience and proprietary glass molding technologies, LightPath delivers consistent, high-quality optical components at cost-effective prices. Their advanced molding process eliminates the need for costly grinding and polishing, reducing production time and enabling scalable manufacturing for both visible and infrared applications.

Trusted by industries such as defense, medical, industrial sensing, and telecommunications, LightPath is a preferred partner for companies seeking reliable, precision-engineered optical solutions that meet the most demanding performance and durability standards.

Geltech™ Molded Aspheric Lenses

LightPath Technologies is a global leader in molded glass aspheric lenses, offering unmatched optical performance with scalable production capabilities.

Our proprietary Geltech™ molded lenses are engineered to deliver diffraction-limited performance across a wide range of applications,

from industrial sensors and medical devices to telecom and defense systems.

Molded Aspheres

LightPath’s molded aspheric lenses are designed by expert optical engineers to deliver high precision and superior performance. They reduce spherical aberrations and can replace multi-element assemblies, simplifying system design. Ideal for high-volume applications in medical devices, laser systems, and industrial imaging.

Molded IR Lenses

Made from proprietary chalcogenide glass like BlackDiamond™, LightPath’s molded IR lenses are optimized for mid- and long-wave infrared use. They support rapid prototyping and scale efficiently to volume production. Optional Diamond-Like Carbon (DLC) coatings enhance durability for rugged environments.

Molding Process

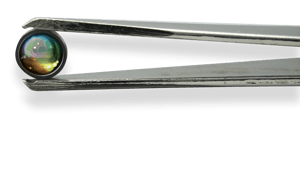

LightPath utilizes a process called compression molding to create precision molded aspheric optics. This process utilizes precision tooling and components in a controlled environment to produce high-precision optics cost-effectively and in very high volumes. In glass compression molding, a glass “preform” (typically a sphere) is heated to a softening point and compressed between two precision manufactured molds to shape the lens into its final form.

Materials

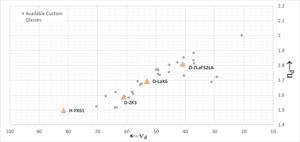

Lightpath produces molded aspherical lenses and molded freeform lenses out of a variety of materials. The Abbe chart below depicts materials that LightPath most recommends using, as well as additional materials that could be used for molded optics.

Contact our team of experts

Our team is here to help. Contact us today to learn how LightPath Technologies can support your project with precision optics tailored to your needs.

.webp?width=160&height=76&name=LightPath-Technologies-Logo-White-removebg-preview%20(1).webp)