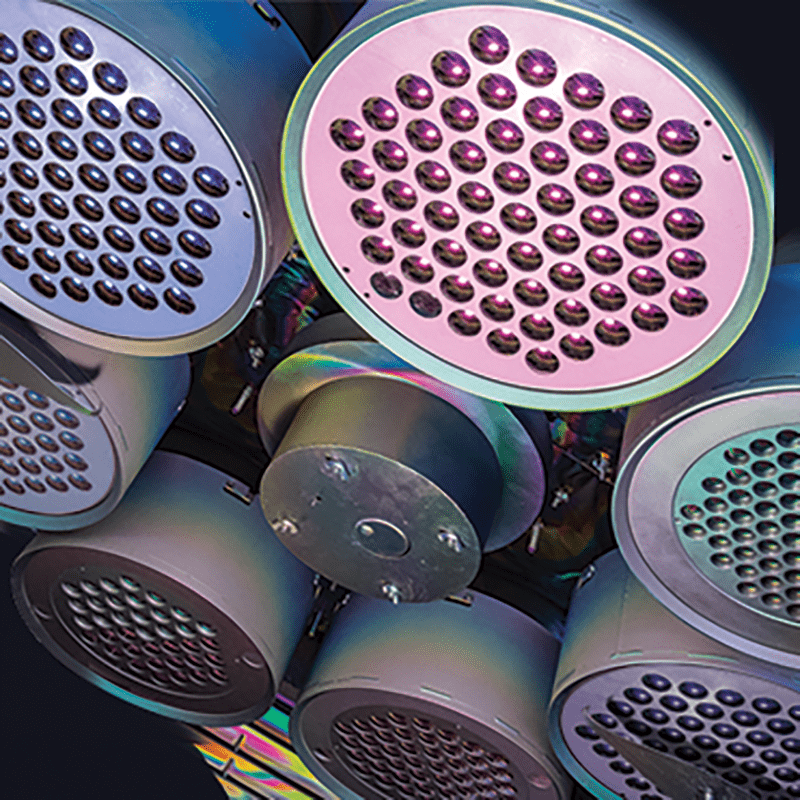

Geltech™ Molded Aspheric Lenses

Precision Optics Engineered for Demanding Applications

LightPath Technologies is a global leader in molded glass aspheric lenses, offering unmatched optical performance with scalable production capabilities. Our proprietary Geltech™ molded lenses are engineered to deliver diffraction-limited performance across a wide range of applications, from industrial sensors and medical devices to telecom and defense systems.

Download the Geltech™ Molded Aspheric Lenses eBook Today!

Why Choose Geltech™ Molded Aspheres?

- Diffraction-Limited Accuracy – Every lens is measured on a phase shift interferometer for verified optical quality.

- Broad NA Range (0.15–0.77) – Tailored for everything from barcode scanning to high-NA data storage applications.

- Custom Form Factors – Cylindrical rods, lens arrays, freeform optics, and insert-molded designs available.

- High-Volume Scalability – Precision glass molding enables consistent results in prototype to production-scale volumes.

- Global Manufacturing Footprint – Vertically integrated facilities in the US, Latvia, and China ensure quality and responsiveness.

Custom Lens Design & Coating Options

From athermal assemblies to dual/triple-band AR coatings, our engineering team works with you to deliver a complete custom lens solution:

-

Complex imaging systems

-

Reflective coatings for aspheric mirrors

-

Insert molding for solder-ready packaging

-

Freeform glass molding

-

Glass dicing and edged lenses with <5µm tolerance

Form Meets Function: Your Lens, Your Way

LightPath’s molding technology supports nearly any configuration:

-

Mounted Lenses for easy assembly

-

Connectorized Collimators for FC/PC, FC/APC, SMA

-

Hybrid Diffractive Lenses for achromatic performance

-

Infrared Variants from 2.5μm to 9.2μm for thermal imaging applications

We support custom holders, arrays, and advanced coatings tailored to your wavelength and mechanical requirements.

Download the Geltech Molded Aspheric Lenses eBook

Perfect for Your Industry

Industrial Automation

Aerospace & Defense

Telecommunications

Medical Diagnostics

Consumer Electronics

Contact Our Team of Experts

Download the Geltech Molded Aspheric Lenses eBook

Ready-to-Ship or Ready-to-Build. With over 100 standard designs in stock and a full custom engineering team on-hand, LightPath offers the fastest path from concept to integration.

Frequently Asked Questions

What’s the advantage of using molded glass aspheric lenses over traditional spherical or plastic lenses?

Molded glass aspheres provide superior optical performance with lower aberrations and tighter tolerances. Compared to plastic lenses, they offer greater durability, thermal stability, and are better suited for demanding environments such as high-power lasers, thermal imaging, and ruggedized industrial systems.

Can LightPath design a custom aspheric lens for my application?

Yes. Our in-house engineering team can design custom lenses and assemblies to meet your exact specifications, including focal length, numerical aperture, glass type, coating, and housing format. We also support thermal and athermal design considerations.

What is the typical lead time for custom or modified standard lenses?

Standard Geltech lenses are typically in stock and ready to ship. For custom designs, lead times vary based on complexity but generally range from 6 to 10 weeks from design approval to shipment.

What coating options are available?

We offer a wide variety of anti-reflective (AR) coatings for UV, visible, and infrared wavelengths, including dual- and triple-band coatings. All coatings meet ISO 9211-4-196 durability standards for abrasion and adhesion resistance.

Are Geltech lenses compatible with fiber optic systems?

Yes. We offer connectorized collimators using Geltech lenses pre-aligned with FC/PC, FC/APC, or SMA connectors. These are optimized for minimal back reflection and high coupling efficiency with standard fiber patch cords.